Featured collection

-

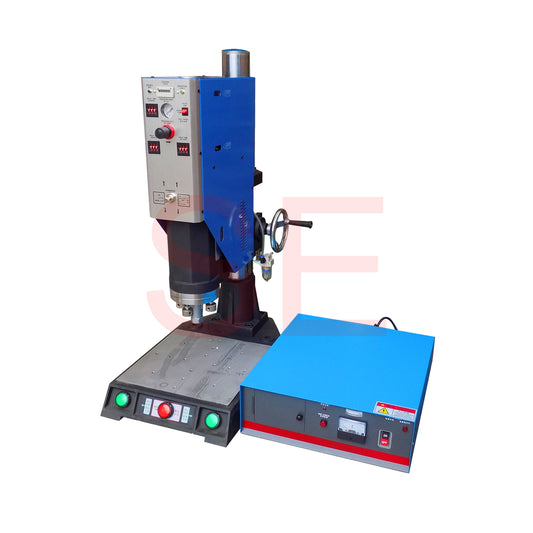

Ultrasonic Plastic Welding Machine 15Khz 2600Watt (SE- 1526B)

Regular price Rs. 185,000.00Regular priceUnit price perRs. 185,000.00Sale price Rs. 185,000.00 -

Ultrasonic Generator box 15khz 3000watt for paper cup welding system

Regular price Rs. 40,000.00Regular priceUnit price per -

Ultrasonic Tape Cutting Machine SE-TCM2022

Regular price Rs. 40,000.00Regular priceUnit price perRs. 40,000.00Sale price Rs. 40,000.00 -

Ultrasonic Welding Generator Paper Cup (SE-2020)

Regular price Rs. 40,000.00Regular priceUnit price per